The new single toggle primary jaw crushers have been manufactured to be reliable in even the most difficult working conditions. Extensive researches have resulted in designing a new crushing chamber with a slight catching angle.

|

Type |

Feed Opening (mm) |

Flywheel Diameter Ø (mm) |

Flywheel Rotation (RPM) |

Drive (kw) |

Weight (kg) |

| FRN1600 |

1600X1350 |

2400 |

170 - 190 |

250- 315 |

90000 |

| FRN1400 |

1400X1250 |

1900 |

180 - 220 |

160 - 200 |

53000 |

| FRN1250 |

1250X1050 |

1600 |

180 - 220 |

132 - 160 |

46500 |

| FRN1100 |

1100X900 |

1400 |

200 - 240 |

75 - 90 |

30000 |

| FRN900 |

900X800 |

1300 |

230 - 260 |

55 - 75 |

19000 |

| FRN750 |

750X550 |

1200 |

240 - 270 |

30 - 37 |

11000 |

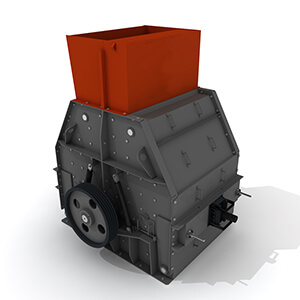

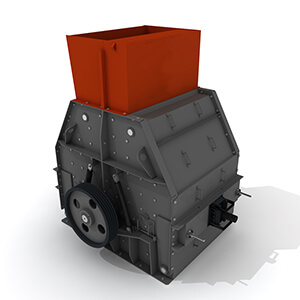

Rup Primary Impact Crusher

|

Primary impact crushers are succesfully used to crush non–abrasive materials with high crushing ratio and high productivity.

|

Type |

Feed Opening (mm) |

Capacity (t/h) |

Rotor Speed (Rpm) |

Drive (kw) |

Weight (kg) |

| RUP65 |

650X700 |

80-145 |

545 |

75-90 |

8300 |

| RUP85 |

850X1000 |

120-250 |

545 |

110-132 |

15000 |

| RUP 110 |

1100X1000 |

160-320 |

380-450 |

160-200 |

28000 |

| RUP130 |

1300X1450 |

280-510 |

380-450 |

250-400 |

35000 |

| RUP170 |

1700X1450 |

580-790 |

380-450 |

355-500 |

58000 |

| RUP200 |

2000X1450 |

740-1020 |

380-450 |

500-900 |

85000 |

Seconder / High Speed Impact Crusher

|

DAL RDS–RDM crushers are high capacity productive machineries designed for quarrying solutions.

| RDM – RDS Properties |

|

Speciality |

Feed Size (mm) (Limestone) |

Feed Size (mm) (Basalt-Granite) |

Capacity (t/h) |

Drive (kw) |

Rotor Speed (rpm) |

Weight (kg) |

| RDM65 |

10–100 |

3–100 |

40–80 |

75–160 |

600–1100 |

9000 |

| RDM65S |

5–150 |

5–120 |

80–150 |

160–250 |

500–800 |

15000 |

| RDS85 |

5–350 |

5–250 |

150–300 |

160–250 |

350–600 |

19000 |

| RDM130 |

10–100 |

3–100 |

80–150 |

160–315 |

600–1100 |

13000 |

| RDM130S |

5–150 |

5–120 |

200–355 |

250–355 |

500–800 |

22000 |

| RDS170 |

5–350 |

5–250 |

250–500 |

250-355 |

350–600 |

29000 |

| RDS170S |

5–350 |

5–250 |

300–750 |

355–500 |

350–600 |

34000 |

|

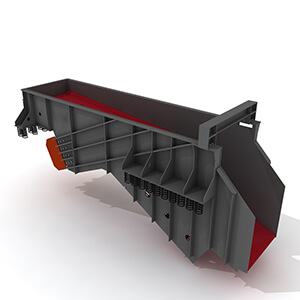

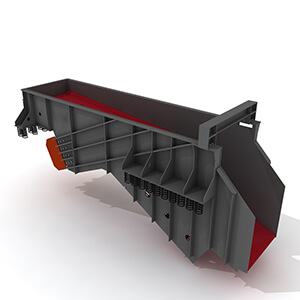

These machines are used to feed primary jaw or impact crushers.The single or double grizzly sections allow to rough out the material, and separate the fine products from the pieces remaining over the grizzly which ensures the capacity increase of the crushers. |

Conveyor rubber in EP 125 or EP 160 quality, with 4 – 5 plies of chord, 10 – 12 mm thickness, endless and with certificate.

|

Type |

Belt Size (mt) |

Drive (Kw) |

Belt Speed (mpm) |

Belt Angle (°) |

| 500 |

5,0- 50 |

5,5 – 22 |

1,1 – 24 |

0 – 18 |

| 600 |

5,0- 50 |

5,5 – 37 |

1,1 – 24 |

0 – 18 |

| 700 |

5,0- 50 |

5,5 – 75 |

1,1 – 24 |

0 – 18 |

| 800 |

5,0- 50 |

5,5 – 75 |

1,1 – 24 |

0 – 18 |

| 1000 |

5,0- 90 |

7,5 – 75 |

1,1 – 24 |

0 – 18 |

| 1200 |

5,0- 90 |

7,5 – 75 |

1,1 – 24 |

0 – 18 |

| 1400 |

5,0- 90 |

11 – 132 |

1,1 – 24 |

0 – 18 |

| 1600 |

5,0- 90 |

11 – 250 |

1,1 – 24 |

0 – 18 |

RAL serie of apron feeders of DAL, are used for extra heavy duty applications in wide ranges. These machines are designed to feed primary jaw and impact crushers.

|

Type |

Dimensions (mmxmm) |

Drive (Kw) |

Capacity (tph) |

Speed (mpm) |

| RAL800 |

800x6000 |

4 |

100-150 |

3,2 - 8,2 |

| RAL1000 |

1000x6000 |

5,5 |

150-320 |

3,2 – 8,2 |

| RAL1200 |

1200x8000 |

11 |

210-590 |

3,8 – 7,5 |

| RAL1500 |

1500x12000 |

22 |

270-850 |

2,5 – 6,3 |

| RAL2000 |

2000x12000 |

45 |

340-1200 |

2,5 – 6,3 |

RAL serie of push feeders of DAL, are used for extra heavy duty applications wide ranges.Proportional hydraulic system lets precise control for feeding.

|

Type |

Table Size (mmxmm) |

Drive (Kw) |

Capacity (tph) |

Stroke (mpm) |

| VAG 800x2000 |

800X2000 |

3 |

50-180 |

50 – 250 |

| VAG 1000X4000 |

1000X4000 |

7,5 |

100-210 |

50 – 250 |

| VAG 1200X5000 |

1200X4000 |

15 |

170-350 |

100- 500 |

| VAG 1500X6000 |

1500X5000 |

22 |

230-550 |

100- 500 |

The movements is operated by a vibrator unit with agjustable eccentric counter weights placed on and outside the screen box.The steel alloy shaft runs on two self-aligning special roller bearings for vibrating operations.

|

Type |

Level |

Size of Sieve (mm) |

Feed size (d/d) |

Drive (kw) |

Weight (kg) |

Rotor Speed (r.p.m) |

| DVE12302 |

2 |

1250X3500 |

150 |

7 |

2240 |

800-1000 |

| DVE12303 |

3 |

1250X3500 |

150 |

7 |

2760 |

800-1000 |

| DVE12304 |

4 |

1250X3500 |

150 |

11 |

3130 |

800-1000 |

| DVE15402 |

2 |

1500X4500 |

150 |

15 |

4200 |

800-1000 |

| DVE15403 |

3 |

1500X4500 |

150 |

15 |

4910 |

800-1000 |

| DVE15404 |

4 |

1500X4500 |

150 |

15 |

5920 |

800-1000 |

| DVE18502 |

2 |

1800X5000 |

150 |

15 |

5870 |

800-1000 |

| DVE18503 |

3 |

1800X5000 |

150 |

18 |

7060 |

800-1000 |

| DVE18504 |

4 |

1600X5000 |

150 |

18 |

8290 |

800-1000 |

| DVE18602 |

2 |

1800X6000 |

150 |

18 |

11680 |

800-1000 |

| DVE18603 |

3 |

1800X6000 |

150 |

22 |

16050 |

800-1000 |

| DVE18604 |

4 |

1800X6000 |

150 |

22 |

18540 |

800-1000 |

| DVE20602 |

2 |

2000X6000 |

150 |

22 |

11680 |

800-1000 |

| DVE20603 |

3 |

2000X6000 |

150 |

30 |

16050 |

800-1000 |

| DVE20604 |

4 |

2000X6000 |

150 |

30 |

18540 |

800-1000 |

| DVE24602 |

2 |

2400X6000 |

150 |

30 |

11680 |

800-1000 |

| DVE24603 |

3 |

2400X6000 |

150 |

37 |

16050 |

800-1000 |

| DVE24604 |

4 |

2400X6000 |

150 |

37 |

18540 |

800-1000 |

DAL Grizzly Screens DGE, are designed for screening applications with high capacity, high screening efficiency, ease of maintenance and mesh replacement and quality manufacturing and workmanskip.

|

Type |

Screen Size (mmxmm) |

Drive (kw) |

Weight (kg) |

| DGE 1036 |

1000X2500 |

7,5 |

4500 |

| DGE 1536 |

1500X2500 |

11 |

7800 |

| DGE 036 |

2000X2500 |

15 |

11700 |

| DGE 2536 |

2500X2500 |

22 |

15600 |

This type of feeders are suitable for the materials smaller than 400 mm. Feeder is driven by means of two vibromotors.

|

Type |

Table Size (wxL) |

Capacity (tph) |

Drive (kw/prm) |

Weight (kg) |

| DVB.0612 |

600X1200 |

100-150 |

2X1,1/1000 |

550 |

| DVB.0815 |

800X1500 |

150-200 |

2X1,6/1000 |

750 |

| DVB.1020 |

1000X2000 |

200-270 |

2X2,2/1000 |

1100 |

| DVB.1220 |

1200X2000 |

250-350 |

2X3,0/1000 |

1350 |

DAL Micronize Screens DME, are designed for fine material screening down to 200 µm.These screens are mounted in a compact design with high capacity, and driven by two vibro – motors which rotates in opposite direction or drive-gear.

| Type |

General Size (mm x mm) |

Screen Level |

| DME05xx |

500X2400 |

2 – 6 |

| DME10XX |

1000X2400 |

2 – 6 |

| DME15XX |

1500X2400 |

2 – 6 |

| DME20XX |

2000X2400 |

2 – 6 |

| DME25XX |

2500X2400 |

2 – 6 |

| DME30XX |

3000X2400 |

2 – 6 |

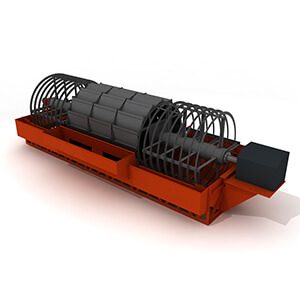

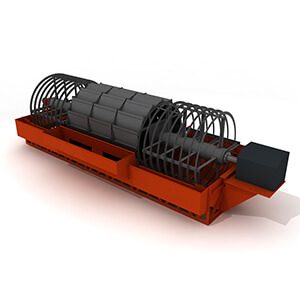

The sand dewatering reclaimer, is a machine which solves the problem of sand reclamation and rinsing.The machine is formed by a moulded tub 15° inclined, the inside of which is equipped with an archimedean screw started into rotation by a gear motor unit.

|

Type |

Capacity (tph) |

Drum Diameter (mm) |

Drum Width (mm) |

Rotation Speed (rpm) |

Torque (N.m) |

Drive (KW) |

| Single Bucket |

2000 |

800 |

0,8~1,25 |

3 |

7800 |

2x7 |

| 2500 |

800 |

0,8~1,25 |

3 |

9800 |

15 |

| Double Bucket |

2000 |

800 |

0,8~1,25 |

3 |

14500 |

22,5 |

| 2500 |

1000 |

0,8~1 |

4 |

16650 |

30 |

| Triple Bucket |

2000 |

800 |

0,8~1,25 |

5 |

21700 |

45 |

| 25000 |

1000 |

0,8~1 |

7,5 |

21700 |

45 |